| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | OEM |

| Model Number : | |

| Certification : | CE , ISO |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union, Paypal |

| Supply Ability : | 100pcs per month |

| Delivery Time : | 15-20 days |

4 Nozzles Dual Cameras Table Top PCB Pick And Place Machine

Description:

| PCB area | 10mm*10mm - 355mm*355mm |

| X Y axis Travel | 420*460mm |

| Z axis moving range | 15mm |

| Placement heads | 2pcs |

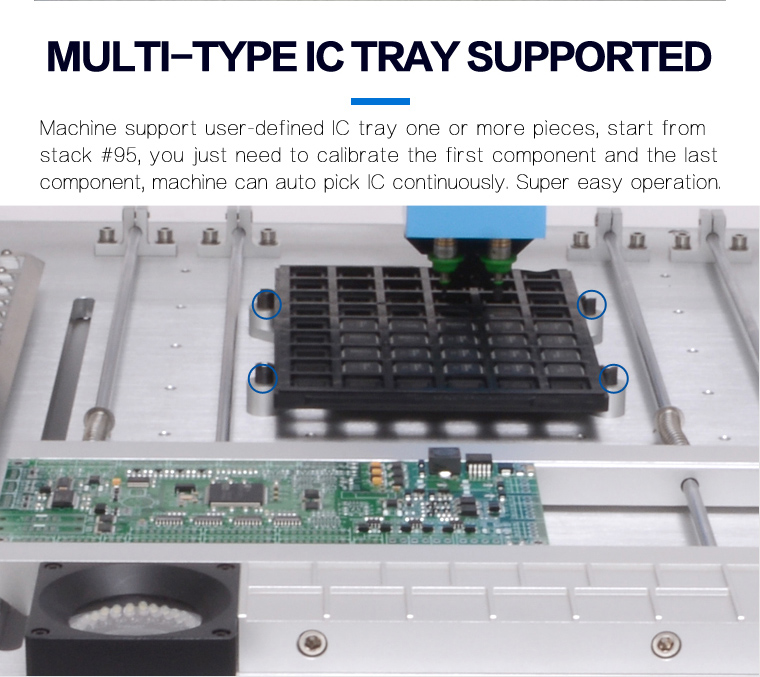

| Feeders | Left 29pcs + right 29pcs 8mm=44pcs, 12mm=8pcs, 16mm=4pcs, 24mm=2pcs, Front IC stack=14pcs, user-defined IC tray |

| Vision system | Dual cameras (up & down cameras) |

| Drive | Closed-loop control stepper servo drive system, make sure never lose step |

| Z axis self-return detection | Yes, prevent nozzles breaking |

| Pull pin self-return | Yes |

| Leakage of material detection method | Vacuum detection, vision detection |

| Touch screen | 7”industry touch screen |

| Main board | Independent research industry main board |

| System | Embedded Linux system |

| Mounting speed | 5000cph (vision off); 3000cph (vision on) |

| Mounting precision | ±0.025mm |

| Components | 0402-5050,SOP,QFN (tape width: 8MM,12MM,16MM,24MM) |

| Machine dimension | L 960mm* W 705mm* H 335mm |

| Vacuum pump | -92KPA (2pcs,build-in, mute type) |

| External air source | No need (machine build-in mute vacuum pump 2pcs) |

| External PC | No need |

| Voltage | 220V (110V), 50Hz |

| Net weight | 75kg |

| Gross weight | 86kg / 116*81*52cm ---- wooden packing |

Competitive Advantage:

1. Convenient software, Embedded Linux System of the machine, very

stable industry main board, independent operation, no need external

computer, operation more easy and convenient.

2. Top and bottom two cameras CCD system correct the position of

each components very accurate, especially for IC (max 22*22mm).

3. Machine support all different kinds of components, from 0402,

0603- QFN, as well as cut tape, tube IC, or bulk IC. Machine can

place multi kinds of PCB.

4. It has flexible PCB clamping fixture, and it has custom IC tray,

front bulk IC feeder, very convenient.

5. The vision also can second correction machine origin point, make

sure origin point correct.

6. 2 heads/ 4 heads with high precise Juki Nozzles with magnet, no

need to disassemble with wrench, nozzles can rotate angle -180

degree~ +180 degree. Placing height is adjustable. 4 serials

machine max components height is 5mm and 5 serails machine max

height is 10mm.

7. 4 serails machine's pull pin automatically return to avoid

nozzles broken, pull pin not be stuck. 5 serial's machine using

Yamaha pneumatic feeder auto feeding, more faster speed.

8. Z axis detection, placement head can auto detect the height and

angle, auto back to origin to prevent any broke.

9. Closed-loop control, X,Y Axis with encoder, motor never lose

steps.

10. PCB calibrate by two vision cameras (machine will auto find 2

points), amend the offset of PCB. Only calirbate 2 points, rest

components will auto correction, calibration can be rapidly and

accurately for PCB, do not need to care about offset, no need to

calculate the input.

11. Comes with vacuum detection, if one component suck crooked, it

will automatically throw it to the feed zone, then pick a new one

to mount again.

12. Comes with vision detection, camera will auto correct component

angle and place onto PCB board in right place. If heads not picking

up components, camera will detect it and go back to pick again, 3

times not picking, machine will alarm and stop.

13. If lack material it will automatic detection, then alarm; after

supply material, then continue working, no need to re-start.

14. Support any number of PCB batch.

15. If no PCB file, or don’t use software load out work file, you

can create a new file to program.

16. Comes with convert tool (PC version), edit work file in

computer and load work file into machine by USB port, quick and

convenient.

17. Support single step.

|